Jan 15,2026

Vinyl sheet piles are increasingly used in marine and flood protection projects as an alternative to traditional steel, concrete, or timber systems. Their resistance to corrosion, long service life, and relatively low maintenance requirements make them especially suitable for harsh environments such as seawalls, riverbanks, canals, and flood barriers. When choosing vinyl sheet piles for these applications, engineers, contractors, and project owners must evaluate a range of technical and practical factors to ensure long-term performance and safety.

Unlike temporary earth-retaining systems, marine and flood protection structures are designed for decades of service under continuous exposure to water, soil pressure, and environmental stress. Selecting the wrong specification can lead to excessive deformation, leakage, or premature failure. Understanding how vinyl sheet piles perform under real-world conditions is therefore essential before finalizing a design.

Environmental Conditions and Exposure Levels

One of the first factors to consider is the specific environmental conditions of the project site. Marine and flood protection environments vary widely, from calm freshwater rivers to aggressive saltwater coastlines. Vinyl sheet piles perform well in corrosive environments, but site conditions still influence material selection and profile design.

Saltwater vs. Freshwater Exposure

In saltwater or brackish environments, vinyl sheet piles offer a clear advantage over steel due to their immunity to rust and electrochemical corrosion. However, UV exposure, wave action, and floating debris must still be considered. In freshwater applications, such as reservoirs or inland floodwalls, chemical resistance and biological growth may be more relevant than salinity.

Temperature and Climate Variations

Extreme temperatures can affect material stiffness and impact resistance. High-quality vinyl sheet piles are formulated to remain stable across a wide temperature range, but projects in cold climates should confirm low-temperature performance to avoid brittleness, while hot climates require UV-stabilized formulations to prevent degradation.

Structural Performance and Load Requirements

Structural capacity is a critical consideration when choosing vinyl sheet piles for marine and flood protection. These systems must resist lateral earth pressure, hydrostatic pressure, wave forces, and potential surcharge loads from nearby traffic or structures.

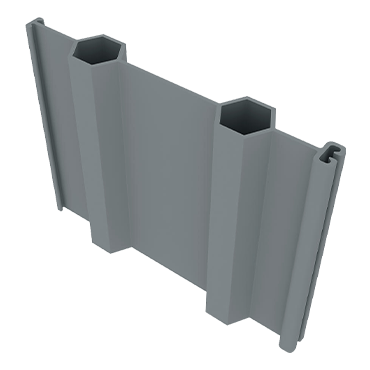

Bending Strength and Section Modulus

Vinyl sheet piles are available in different profiles and thicknesses, each offering a specific section modulus and bending strength. Projects with higher wall heights or greater water level fluctuations require profiles with increased stiffness to control deflection and maintain stability.

Allowable Deflection Criteria

Unlike temporary shoring, permanent marine structures often have strict deflection limits to protect adjacent infrastructure and prevent erosion behind the wall. Designers should ensure that the selected vinyl sheet pile system meets allowable deflection criteria under both normal and extreme loading conditions.

Interlock Design and Water Tightness

For flood protection applications, controlling water seepage is just as important as structural strength. The interlock design of vinyl sheet piles plays a major role in determining overall wall performance.

Interlock Strength and Durability

Strong, well-designed interlocks ensure load transfer between adjacent piles and reduce the risk of separation under hydraulic pressure. In marine environments, interlocks should also resist wear caused by wave motion and debris impact.

Seepage Control Options

Although vinyl sheet piles are not fully watertight by default, additional measures such as sealants, welded caps, or integrated water barriers can significantly reduce seepage. The required level of water tightness depends on whether the structure functions as a seawall, floodwall, or erosion control system.

Installation Methods and Site Constraints

Installation feasibility is another key factor when selecting vinyl sheet piles. Marine and flood protection sites often present logistical challenges, including limited access, soft soils, or environmental restrictions.

Driving and Installation Techniques

Vinyl sheet piles are typically installed using vibratory hammers, water jetting, or a combination of methods. Their lighter weight compared to steel piles can reduce equipment requirements and installation time, particularly in remote or environmentally sensitive areas.

Soil Conditions and Embedment Depth

Soil type directly affects embedment depth and wall stability. Soft clays, loose sands, or organic soils may require deeper embedment or anchoring systems to achieve the desired performance. A geotechnical investigation is essential before finalizing pile length and profile.

Durability, Maintenance, and Service Life

One of the main advantages of vinyl sheet piles in marine and flood protection is their long service life with minimal maintenance. However, not all products offer the same level of durability.

- Resistance to corrosion, rot, and biological attack

- UV-stabilized formulations for long-term outdoor exposure

- Color stability and surface wear resistance

When properly specified, vinyl sheet piles can achieve service lives exceeding 50 years, making them a cost-effective solution for permanent marine infrastructure.

Cost Considerations and Lifecycle Value

Initial material cost is only one part of the overall investment. For marine and flood protection projects, lifecycle cost often provides a more accurate measure of value.

| Cost Factor | Vinyl Sheet Piles | Steel Sheet Piles |

| Initial Material Cost | Moderate | High |

| Maintenance Cost | Low | High |

| Corrosion Protection | Not Required | Required |

For long-term flood protection and marine applications, the reduced maintenance and extended lifespan of vinyl sheet piles often offset their initial cost.

Regulatory, Environmental, and Sustainability Factors

Many marine and flood protection projects must comply with strict environmental regulations. Vinyl sheet piles are often favored because they do not leach harmful substances into water and can be manufactured using recyclable materials.

In environmentally sensitive areas, their quieter installation and reduced need for chemical coatings can help projects meet permitting requirements while minimizing ecological impact.

Conclusion: Making an Informed Selection

Choosing vinyl sheet piles for marine and flood protection requires a balanced evaluation of environmental exposure, structural performance, installation conditions, durability, and lifecycle cost. By carefully assessing these factors and working with experienced designers and suppliers, project stakeholders can select a system that delivers reliable protection, long-term value, and sustainable performance in challenging water-related environments.

English

English 中文简体

中文简体